What are

/r/3018CNC's

favorite Products & Services?

From 3.5 billion Reddit comments

The most popular Products mentioned in /r/3018CNC:

The most popular Services mentioned in /r/3018CNC:

The most popular reviews in /r/3018CNC:

I'll post on Thingiverse later today. I had to take apart the unit to drill 3 holes for M3 bolts and replaced the current 8mm M4 bolts with 10mm.

It has a 15 deg angle to make easier to read.

The ribbon cable is just long enough.

Here is the tinkercad link which I use a lot for making simple parts.

Genmitsu 3018 Offline Controller mount

A better shielded USB cable w/ the ferrite bead on the CNC end would help.

I had the same problem and upgrading to this cable fixed it.

https://www.amazon.com/gp/product/B003L1380E/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Best option from me would be a 1.6mm engraving bit. https://www.amazon.com/dp/B0B2JWT4WY?ref=ppx_pop_mob_ap_share Cheap and work great.

500mm/min (or slower) 0.50mm DOC Max Spindle RPM (10000)

I bought a $20 parallel port card on amazon. https://smile.amazon.com/gp/product/B001Q7X0Z8/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 is unavailable right now, but any one like it should work.

I had really bad problems with the stock spindle and usb cable. I switched to a shielded mono price usb cable with a ferrite bead on the cnc side of the cable, and it hasn’t disconnected since.

https://www.amazon.com/dp/B003L1380E?ref=ppx_pop_mob_ap_share

buy two 2060 alum extrusions the length of the side 2040s (or cut em, they cut easy with circular saw), the associated plate clamps to clamp it ontop of existing 2040 and you have another 40 or 60mm to fart around with depending upon where you mount the uprights. the mcmaster link is just to show what i am talking about, im sure you can find it on amazon.

Small flat endmills. like this or equiv. is what I use. My boards are generally pretty small (my blanks are 7x10cm. If you have lots of holes and it will be a pita to drill em by hand, something like this as well.

If you plan on cnc drilling, buy a couple of bit sets, it will take ya some time on the learning curve to get the programming right and you will break the lil one.

Also, start reading on height mapping - this is an absolute must for good boards as all of em are a bit warped (and use a pretty high density of points if your board is crowded or very detailed). If you are only going to use the same size blanks, then make a pocket jig out of mdf or something when you first get the cnc, if you are cranking the same board out over and over makes it easy as you can do the individual steps on several boards very quickly.

I wouldn’t bother with paint personally. Sydien 1Pc CNC 3 Wings Spoilboard... https://www.amazon.com/dp/B08GQM8YZR?ref=ppx_pop_mob_ap_share that’s the resurfacing bit I got to smooth out the spoil board. You will need to order a 1/4 inch collet for the machine. There are plenty of YouTube videos about spoil board surfacing. I bought the same spoil board you have and have kinda started to regret it. It has to be that thick to accommodate the mounting hardware but u lose a lot of capability in ur z axis because the spoil board is so thick. For the most part I can still cut out most of what I want but sometimes the retract length when starting the program will activate the positive z limit switch.

Looking at all the upgrades neede this would also fit the budget, would this be a better pick than upgrading? https://www.amazon.nl/dp/B08FC59SLB/ref=cm_sw_r_apan_glt_i_YKX0X3WRKXGAKZEY4ZZH?_encoding=UTF8&psc=1

I think this is using mach3, but since i don't know grbl or mach3 i think that might not be my biggest problem

Looking at all the upgrades neede this would also fit the budget, would this be a better pick than upgrading? https://www.amazon.nl/dp/B08FC59SLB/ref=cm_sw_r_apan_glt_i_YKX0X3WRKXGAKZEY4ZZH?_encoding=UTF8&psc=1

I think this is using mach3, but since i don't know grbl or mach3 i think that might not be my biggest problem

You have to keep in mind that the frame of that machine is very weak, especially on the horizontal axis X, and a 300 or 500W spindle is much heavier than the default one, and will increase these defects.

If you intent to cut or sculpt wood, the default spindle can do the job. With it, I'm able to cut up to 20 mm thick pine wood (although slowly, 1.5 mm passes).

If you want faster speeds/larger bits/harder materials, there are stiffer versions of the machine on the market such as this one, which is sold with a 500w spindle: https://www.amazon.com/ANNOY-TOOLS-Machine-3018Pro-Upgraded/dp/B097DBQV9K/

You're sentiment is pretty common amongst 3018 users who have used it to any extent. The 3020 Pro Max definitely looks like it addresses the issue and the YouTube influencers that reviewed it extol the 3020 praise. Sainsmart says they should be shipping them in April so I look forward to hearing what folks have to say.

If I don't go with the "name brand" pro max I will likely get one of the 3018 Max clones off of amazon (like this one) as they have the 4040 extrusion for the frame and it looks like 2040 for the X axis as well as 12mm rods. Which is an upgrade from the 2040 frame, 2020 X axis, and 10mm rods. I know it wouldn't be as beefy as the 3020 pro max but it "might" work for me lol.

Given the consent on spindle usage for hardwood I'll probably just get the 500w spindle (brushed) upgrade right out of the gate and if I'm lucky be done with it.

^^^I'm with this guy^^^

Run a separate power supply for your spindle.

On the stock board you can apparently control the spindle speed using the laser PWM output through one of these

Provided your 3080 is a 3018 typo, the extension sets are all basically the same with some little bells and whistles here and there. I bought this one for the knobs. The extended aluminum bed depends on what you want to do. This mill is for light work for me, so I didn't need the double sized bed. I just put a larger sacrificial board on the original one and it works just fine for what I want.

~$20 on Amazon for 2 pieces of 450mm 2040 extrusion, $30ish for a set of drill tap bits if you don't have access to some already.

And then you'll have 2 extra pieces of 2040 extrusion. You wouldn't want that valuable material to go to waste, so might as well start building up a 2nd machine ;)

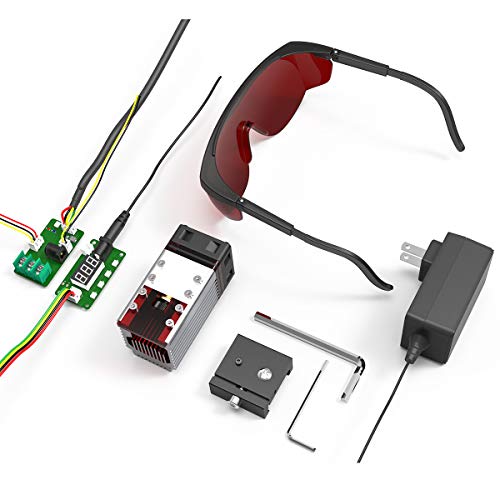

You are correct it’s a 10w (optical) laser which draws 80w power. This is the unit I’m talking about:

ANNOY TOOLS Module de gravure 80 W, puissance de sortie 10 W, accessoires pour graveur laser, entrée 12 V, contrôle PWM/TTL, design de protection des yeux, pour machine CNC/routeur/Arduino/imprimante 3D, etc https://www.amazon.ca/dp/B09MFLRFVG/ref=cm_sw_r_cp_api_glt_i_X2N71DNABMZ7SSSMD86G

I have this one

AVAWO DC 24V15A 360W Switching... https://www.amazon.com/dp/B0146IAXYO?ref=ppx_pop_mob_ap_share

It runs the GRBL computer, my switch panel , and LEDs via with Buck Converter.

I'm still useing the GRBL computer to control the motor.

at that price point, you can get a much more powerful NEJE laser.

This 7.5W one is a popular option.

and if you need air-assist you should get a larger (and possibly quiter) pump than the one in the kit you linked.

with a 7.5mm laser, you might be able to cut 8-10mm thick (depending on the material). and if you don't need that much power, just run the laser at 50%, essentially extending the diode's life significantly.

Daedalus 0-100V PWM DC Power Supply Motor Speed Controller Switch 6A, Mach3 Supported https://smile.amazon.com/dp/B07ZSXGYXL/ref=cm_sw_r_apan_glt_fabc_3NXFZNGASYPB9DQ5X6B6?_encoding=UTF8&psc=1 I used this one. Just adding a power supply will not control speed without either PWM control or a potentiometer. This will do both. I am using a different board from the stock one so I don't know if the stock board will control speed through this but if not you can use the potentiometer (knob) that comes with it.

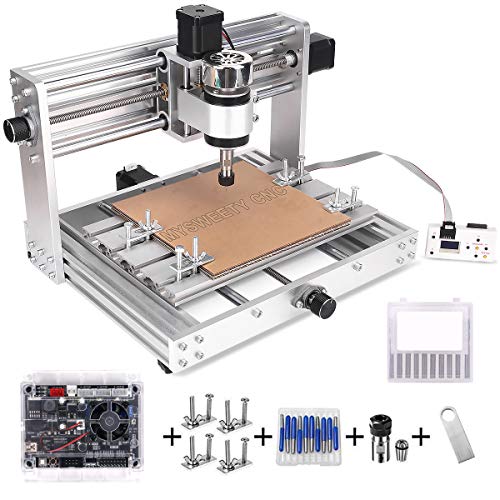

I agree you should replace your board if you are not able to troubleshoot and repair yourself. Ali has the best prices but you can also find these on Amazon if you want it faster. 30-50 dollars on most. Here is a link foe one. I am not saying you should buy this one. Just wanted to illustrate what is there. CNC Control Board, MYSWEETY GRBL 3 Axis Engraving Machine Controller Board for DIY Mini CNC Wood Router Engraver Machine https://smile.amazon.com/dp/B07S2R59N6/ref=cm_sw_r_apan_glt_fabc_XFNMHNTR3JRJHYGR1RGK You need to choose what is best for your needs.

I'm pretty well set on the Daedalus Pro Max but could be convinced to go another route if there's a deal to be had on another unit.

But also, if there's going to be a sale on accessories like lasers, upgraded spindles, expansion kits, etc, it would be nice to have it on the radar. The normal BF ads don't really cover this type of equipment.

After your note about the Max category I'm down to the MySweety 3018 Max or the Daedus 3018 Pro Max.

They look like they might be identical so I'm leaning toward MySweetie just because I've seen the name more frequently.

Thanks for the recommendation on bits and acrylic. I haven't even bought the thing yet and I'm already eyeballing all kinds of upgrades and goodies.

The Sainsmart 3018 ProVer is a all aluminum frame, it has:

z-probe

e-stop

limit switches

newer board

newer offline controller

This CNC 3018 Pro Max is actually a Pro version with the side acrylics, not a Max version.

If you google for 3018 max, you'll see an all aluminum frame, different spindle, manual adjustment knobs, etc.

Example: https://www.amazon.com/MYSWEETY-3018Pro-Engraver-Controller-Extension/dp/B08332BR39

It's basically a Sainsmart 3020 without the X linear rails.

So, what materials / work do you plan on doing?

I ordered this when I was building my end-stop/limit switches. It's a bit of overkill as far as quantity goes but I have used them elsewhere. https://www.amazon.com/gp/product/B014YTPFT8/ref=ppx\_yo\_dt\_b\_search\_asin\_title?ie=UTF8&psc=1

I'm finding this one. Looks of the same construction but not the one you have. ANNOY TOOLS 2060U Z-Axis Slide Module Screw Slide Table Linear Rail Guide, 60mm Stroke Stage Actuator kit for DIY CNC 3018 Plus Z Axis Router Controller https://smile.amazon.com/dp/B099W1RWH8/ref=cm_sw_r_apan_glt_fabc_9KRZGFQX1JJ994QMYTCQ

What spindle speed and what cutter. Your results should be better with the right tool, speed, feed, and depth of cut. I would use something like this HQMaster 1/8" Shank Downcut End Mill Sprial CNC Router Bits Down Cut Tungsten Carbide Milling Cutter Set 5pcs https://smile.amazon.com/dp/B08THHYLPL/ref=cm_sw_r_apan_glt_fabc_0DC9ZAV3J3DWF0KVBVD8 You can also find tools really cheap on Ali express if your willing to wait.

I just bought THIS ONE and while I have not tested the electronics yet, it came fast, well packaged, the plastic parts are all injection molded and well finished, and I think you'd be hard pressed to buy the extrusions, bearings, rails, and motors individually for the price. I am turning this one into a pen plotter but I may buy another to make a laser engraver.

Thank very much for your detailed response! Is this the model you have or suggest? https://www.amazon.com/SainSmart-Genmitsu-3018-PROVer-Switches-Emergency-Stop/dp/B07ZFD6SKP/ref=sr\_1\_1\_sspa?dchild=1&keywords=Genmitsu+CNC+3018&qid=1632970678&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUExS0tJVzZLMFlLN...

This guy comes with a laser and a spindle. Shop around and read the reviews. Upgrade Version 2 in 1 3000mW Engraver CNC 3018 Pro GRBL Control DIY Mini CNC Machine, 3 Axis Wood Router Engraver with Offline Controller + CNC Router Bits + ER11 Extension Ro https://smile.amazon.com/dp/B07HNWT572/ref=cm_sw_r_apan_glt_fabc_BFPFXVXYVD29TCJF9MM9?psc=1