What are

/r/ElegooSaturn's

favorite Products & Services?

From 3.5 billion Reddit comments

The most popular Products mentioned in /r/ElegooSaturn:

The most popular reviews in /r/ElegooSaturn:

You can print the threads directly down to M3 or so, however the threads are delicate. You're better off with inserting a steel nut or using this type of screw: https://www.amazon.com/HELIFOUNER-Phillips-Computer-Self-Tapping-Electronic/dp/B081DVZMHH/

I have a nearly identical setup but with a larger plug-in rotating platform, and I use a clear ice bucket filled with water, which I've found helps with curing. Here's the bucket I use: https://www.amazon.com/dp/B00J0HYRYO/ref=cm_sw_r_cp_apa_fabc_6GWVZ9F5P7HDEH5XTFCS?_encoding=UTF8&psc=1

It fits even the largest Saturn part and is still small enough to fit in the enclosure. I also have both the leds and platform connected to a smart plug so it turns off after my specified curing time.

Crossposting from /r/3Dprinting.

I saw the Creality enclosure and it occurred to me that it's basically just a giant storage container. Resin printers don't need as much in the way of thermal protection or fireproofing BUT some resins do have a nasty smell.

I work from home and sit ten feet away from my printers. My sister is up here too and she has a really sensitive nose. One small slit in the back for the power cord and these solve that problem completely. Any kind of clear storage bag with a zipper should work great. These are the ones I bought because they fit the Saturn.

Unzip the top and it collapses down so you can access the rest of it unimpeded! If it wears out eventually, well they cost $4 each so that's no big deal.

This one seems to have one the correct size.

<strong>https://www.amazon.com/dp/B08KPM96C3?ref=ppx_yo2ov_dt_b_product_details&th=1</strong>

Don't worry about the one hole. I have the Jupiter and it has one hole for ventilation too. attaching a quality exhaust fan was the best thing I ever did. It pulls out all of the fumes. Before I did that, the Jupiter has so much resin in it, that if I printed multiple times within a week, my throat would be irritated by being in the room too much. The exhaust absolutely works and is the best thing I ever added to my setup. It takes care of the fumes just fine.

Now in the case of the Jupiter the cover is a bit different. It has a door and there's a gap and air can be pulled through it. It would be better to force clean room air in one port and exhaust it out another with two desperate fans but it still works very well with just the one exhaust fan.

You can of course drill a second hole and attack an intake yourself. The annoying thing about the saturn cover is you have to lift the entire thing off with the hoses attacked and have the room to put the removed cover near by when working.

When I need to filter, I picked up one of these stainless funnels that have two different sized mesh inserts. They work well, and can be easily washed off with IPA. https://www.amazon.com/dp/B094JD7T7V

But most of the time I just let everything settle for a bit, then put a bit of old support structure in the corner of the vat, then use the tank clean feature that exposes the entire bottom layer for 15 seconds. You can peel up everythihng in one go, and that usually saves the hassle of dumping the resin through a filter.

My digital caliper says 129mm for the short side. The long side is too long for it, but my metric tape measure says 224mm for the long side.

I just got my Saturn 2 a few days ago from their Black Friday sale and haven't used it yet. I'm thinking about adding a magnetic flex plate, which is what led me here after being appalled at the WhamBam prices and reading comments that the water washable resin (which is what I got) eats away at the adhesive on their magnet. Does anyone have any ideas on what sort of adhesive, short of a permanent glue (like Crazy Glue) would work well? I don't want to drill through the plate to rivet on a magnet, which even then would lead to resin seeping between the magnet and the flexible build plate.

​

I did find this on Amazon for $27: https://www.amazon.com/dp/B0BKRJXVF9/?coliid=I15ABXKECCYDER&colid=362XT03S7P3WS&psc=1&ref_=lv_ov_lig_dp_it. It's unclear if the tab extends beyond the 129 mm or is part of it. There aren't yet any reviews.

Are you talking about one of these?

Hey since I'm from europe I can't find the screws you mentioned (M3 with the -0,5).

Can you tell me if these are the right one? It says m3 and 8mm

This is the Aus store, but I assume there's similar in the US and other countries: https://www.amazon.com.au/gp/product/B099ZJKBSM/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

I got that for the Saturn, and it's been great. I've probably done at least 30 prints with it over the past few months and there's no signs of issues with the adhesive that some of the lower reviews have suggested. I did notice that these listings say 24 hours to let it set once you've applied the magnet, but I went with 72 hours as per Wham Bam's recommendation in their videos. They say it's to let "the 3M adhesive cure", and the magnets that come with the cheaper ones also use 3M adhesive, so I just applied the same logic.

wow 8C you got me excited! So no other space heaters or nothing, just that belt around the reset vat in a cold garage? Thank you SO MUCH! Can you look at this link and tell me if this is something you're talking about.

https://www.amazon.com/gp/product/B001D6IUB6/ref=ox\_sc\_act\_title\_1?smid=A3EB9LRCOJ90E&psc=1

In 4 years of resin printing, using printers from Elegoo, Anycubic and Epax. I've never had a model rip the fep. Either Elegoo is putting garbage fep on the new Saturn 2 models or you are destroying the fep trying to peel remove the failed print from it.

Switch to nfep, which is better than fep as prints stick to it less. You can cut it to size for your Saturn 2.

https://www.amazon.com/Siraya-Tech-NFEP-Film-Performance/dp/B09P881YLB

I've used this Siraya nFep with perfect results.

Yes, I do have a question. Besides being able to monitor the environment with an app. Is there anything special with the inline fan that you suggested? I was thinking about saving 100$ and getting a more standard inline fan like this.

I ordered 2 of these to put along my wall, they've worked out great. Perfect height to stand and work at:

https://www.amazon.com/gp/product/B08BZCSX9H/ref=ppx_yo_dt_b_asin_title_o08_s00?ie=UTF8&psc=1

I have used this and it makes the job VASTLY easier.

These things are great if used within their (very low torque <0.2nm) limitations. That means you usually only need to hand-tighten the last quarter turn or so, depending on the application.

With installing FEP, because the material is in the threads it can cause more binding and thus needs a little more hand-cranking to finish the job, but the powered part will get most of the screws at least 4/5ths installed.

With the same thing in mind, it's also a good way to remove all those screws too -- you just need to get them started by hand. The screwdriver auto-locks when not powered, so it works like a normal screwdriver until you press one of the drive buttons.

I've only changed the FEP once, I used Bondhus T-Handle balldrivers. Once you break the screw free you can spin the T-Handle with your fingers tips to quickly remove the screws. It works well and isn't as painful as using an allen key. I used a pair of pointy tweezers to pierce the FEP before putting the screw in.

The T-Handle set it a little expensive but I've had mine for years and use it all the time.

Here’s a calibration model link:

https://www.thingiverse.com/thing:4910573

Load it up and watch through the tutorial video on it. Even with added time and base layers it only takes me 12 minutes to print.

Lightly lube and dry the tray to avoid prints sticking:

3-IN-ONE - 120032 Multi-Purpose... https://www.amazon.com/dp/B00J25JDDY?ref=ppx_pop_mob_ap_share

Some even call for lightly sanding the build plate with 120 grit so the models stick better.

Finally, yes you were going to burn through lots of resin before you get it all figured out.

I'm using this mini heater and it seems to do the job. Cords currently run under the edge of the lid, leaving a small gap. I made/printed a small stand to hold the heater in an upright position so the cord can come out the bottom. It sits one of the back corners and vents heat upwards. This model has a self-resetting thermal fuse so it's not bottom barrel on safety.

https://www.amazon.com/dp/B07573FKSG

I use it combined with this thermostat outlet:

https://www.amazon.com/dp/B01I15S6OM

Keep in mind the resin temp will trail the air temp, since air isn't the best conductor of heat. I found that setting the thermostat to 80F (with the probe at the base of the Z-tower, opposite side form the heater) resulted in a resin temp of about 72F during pre-heating (within 60 minutes, maybe faster, I didn't check). Once printing starts, the UV/chemical reaction heat brings the resin temp up to a similar 78-80F.

I considered brewers belts in the event air heating wasn't working, but they're lower wattage (usually about 20-30W), though with the advantage of more directly applying the heat to the resin (at least if you have a metal vat). I preferred not to deal with another thing attached to the vat, making vat handling or cleanup or random drips more complex, but I would have tried that next if the air heater didn't work for some reason.

Air heating is working well for me though, and should be a lot nicer once the wiring is cleaned up with a riser!

It took me a bit but I found them on Amazon. No longer called FEPs but PFA Release Liners is what they're called. Different material or something.

ELEGOO 5PCS PFA Release Liner... https://www.amazon.com/dp/B09ZXLQWWH?ref=ppx_pop_mob_ap_share

Get some Goof Off and plastic razor blades. Add a little of the goof off to the screen in a well ventilated room or outdoors, let it sit for a minute or two, then scrape with a plastic razor. Repeat as necessary.

This is neat, and I'm glad somebody stepped up to fill the niche. Half the site is Lorem Ipsum, which is a little worrying, but I'm guessing they're new and still building it out.

I've seen a lot of people using brewer's belts, which seem like essentially the same thing.

I'm not going to put a current-resistance heater anywhere near alcohol, when I'm not there to monitor it. Especially one I've built myself, like a lot of links are suggesting.

I've heard of reptile mats scorching countertops.

Get a seedling grow mat; they use infrared heating so they're completely safe to leave unattended.

When I checked yesterday, it showed "sold by: Elegoo Official, shipped by: Amazon"

The Amazon listing is literally an option on the standard Saturn page, so, it has to have been added by the Elegoo account.

Either someone with Elegoo's Amazon account added it, or Amazon has a serious security vulnerability.

Edit: here's a link to the Amazon USA page: https://www.amazon.com/ELEGOO-Monochrome-Reducing-Protector-8-6x4-8x9-8/dp/B0BBF1PBSW?th=1&psc=1

Thanks, yeah I might do something similar.

Something like this would be the right size and I would only need a tiny heater inside to regulate the temperature. https://www.amazon.co.uk/dp/B01LZGOTV6/ref=twister_B08WYCMZSR?_encoding=UTF8&th=1

Here you go:

It’s labelled as Bundler Bucket for some reason but here it is, hope it’s what you were looking for.

Sure thing!

The grey piece is just a piece of wood, painted, cut to fit the width of the window, and sealed around the edge with weather stripping. It just sat in the bottom of the window at all times.

The fan is a pre-wired one that I found on Amazon (https://www.amazon.com/dp/B009OXTWZI?ref=ppx_pop_mob_ap_share) that plugged directly into a wall outlet. The fan is attached to a bilge hose with a part that I modeled myself, but unfortunately I no longer have the file for. It only took a couple minutes to make, I'm sure just about anybody could model it.

At the printer end, the fan is attached to another printed part that I found here on Reddit. (https://www.reddit.com/r/ElegooSaturn/comments/ogxx5n/think_you_might_like_this_msg_me_for_files/?utm_medium=android_app&utm_source=share)

I also have the elegoo charcoal filters running inside. It all seemed to work pretty well together.

I was dealing with those same warping issues, even laying out a thick wall of supports was only partially mitigating the warping. I switched to this resin, and can't recommend it enough. Completely different results; no warping from gravity sagging, even with a sparse minimum of supports on large prints, once you get the calibration dialed in. Printed about 10kg worth of stuff with the resin so far.

I hope this helps

The two best things you can do are to add the flex plate and get a razor blade scraper with yellow plastic blades. Sometimes flexing the plate doesn't quite pop the prints off, but just a tiny bit of pressure with one of these plastic scraper blades and they will pop instantly. These are a must have IMHO:

I use a (waterproof) kombucha heater belt around mine: https://www.amazon.com/gp/product/B08NY61YNJ/

It is also called a seed-starter heater. Different from hot pads for lizards, etc. because it only raises the temp by 10-20 degrees F. I use mine with an inkbird temperature-sensing outlet to dial in specific temps, but really that isn't needed. The belt isn't going to have thermal runaway or start a fire...

No sorry. I bought one of those plastic boxes of screws of the same size with multiple lengths in them and just used the ones that looked the right size. If it helps:

https://smile.amazon.com/dp/B08H24W42K?psc=1&ref=ppx\_yo2ov\_dt\_b\_product\_details

Grab one of these, you won't regret it. They come in 3 packs now instead of 2 but the peace of mind is worth it.

Siraya fast navy gray is a dream. It's affordable, precise, fairly durable, prints well, and looks nice. Like all resins, It's a bit brittle so I mix 20% tenacious into it so my swords and spears don't break, but that's a more advanced move.

Do NOT cheap out by getting some weird brand because it's affordable. You'll blow half your bottle on failures and/or have difficulty washing and it'll make you think the hobby is awful. Use good tools for good results.

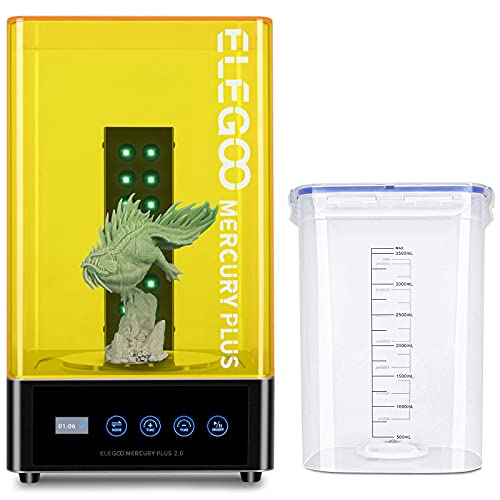

A wash and cure machine is optional, but I would recommend a curing station of some sort, I have found that sun curing takes ALOT longer and has to be really sunny to be effective. I use and ultrasonic machine to wash my prints and this is my curing box. I have all the way up to the jupiter and have not had any size issues. https://www.amazon.com/Resin-Curing-Light-Power-Compatible/dp/B08XXM2QHD/ref=sr_1_10?crid=1P24E1J60GCMG&keywords=curing+station&qid=1658854614&sprefix=curing+station%2Caps%2C149&sr=8-10

copy/pasting from a prior thread:

So, I have a dirty wash and a clean wash. My method is:

- Soak and agitate in the dirty wash for several minutes. I also lean the scraper into the dirty wash. When I lift it out and the smeared resin on it has slid off into the wash, I proceed to the next step.

- fill a small syringe from the clean wash and spray any crevices that I notice.

- Transfer to the clean wash and agitate there for about a minute

- spray down with a wash bottle full of virgin alcohol

- put in warm water to remove alcohol and soften supports

- transfer to distilled water for curing (water-curing is a little faster, and doesn't require the print to be dry before curing

SO. the wash bottle is basically the flossing step for you, but it's cheaper and will have less pressure (as it stands, I still spatter myself with the wash bottle so I can't imagine how much a flosser would splash)

Bonus of this method is I'm always moving a little alcohol down to the dirty wash, which counteracts evaporation.

My friend, I know from experience you can absolutely cross thread by hand.

If you're looking to fix these printers, and get them running, you might also consider threaded inserts that you glue in place. Here's an Amazon link: https://www.amazon.com/s?k=threaded+inserts+for+metal&sprefix=threaded+inserts%2Caps%2C192&ref=nb_sb_ss_ts-doa-p_5_16

Another option is to forego the screws and upgrade to some sort of clamping mechanism. I had something like this in mind, but it would require more modification and tinkering to get working: https://www.amazon.com/TING-Toggle-Antislip-Horizontal-Release/dp/B0B3MLLLJQ/ref=sr_1_2?crid=2BPFYN9JZSYVF&keywords=mounted%2Bclamps&qid=1657540340&sprefix=mounted%2Bclamps%2Caps%2C123&sr=8-2&th=1

Hope this helps you back on the path to profitability.

You are boned, my dude. :)

If you reach out to Elegoo they may offer to send you one under warranty but don't expect it quickly; when they sent me warranty parts it took a good month between the back-and-forth and shipping before I had them.

If you don't want to wait you can get them from Amazon.

This is the one I use

Geeetech UV Curing Light Box for LCD/DLP/SLA 3D Resin Printer Model, DIY 405nm UV Resin Curing Box with 360°Driven Turntable, Intelligent Time Control Resin Curing Station, Fast Curing Machine GCB-1 https://smile.amazon.com/dp/B08VS74MJ6/ref=cm_sw_r_apan_i_HA1RXKAV2AYQFYVXQ182

I just checked Amazon and it's showing them in stock. ELEGOO Metal Resin Tank for ELEGOO Saturn 3D Printer, FEP Pre-Installed, with Lid and 3 Allen Wrench, Resin Vat for ELEGOO Saturn https://www.amazon.com/dp/B08NSL97F3/ref=cm_sw_r_apan_i_6A89S4GYG2FNWMREX22G?_encoding=UTF8&psc=1

This works from Amazon

You will have to turn the exposure on and rotate the polarizer so that the screen turns almost completely dark as much as possible. Then cut it to fit. Then tape down the edges and place a screen protector over it to never have to do it again.

I did this based on another users experience and it worked for me.

Just out of curiosity I just looked on the US amazon store Elegoo's shop has replacement Saturn vat's for delivery as early as tomorrow.

https://www.amazon.com/ELEGOO-Saturn-Printer-Pre-Installed-Wrench/dp/B08NSL97F3

Get this and install it before you get any blemishes on the screen to avoid any bubbles.

Mach5ive Screen Saver

https://www.amazon.de/gp/product/B09NQZWLHV/ref=ppx_yo_dt_b_asin_title_o06_s00?ie=UTF8&psc=1

​

I bought these, and they work fine.

I use Saran Wrap for this purpose. Not as elegant, or durable, and doesn’t protect from light, but it does seal it completely. I wrap it around the bottom of the vat as well for extra FEP protection.

But I’ve searched for silicone vat lids and I’ve gotten frustrated too. An idea I had was to order those reusable silicone stretch lids for food storage, like these for example. I couldn’t easily find ones that came in a pack of just the one size I need, though. They also aren’t opaque. I thought about how they could be made opaque if I use some black silicone glue or caulk to “paint” over the stretch covers just where light would get through to the resin.

Another idea I’ve had is to use a rectangular piece of plastic lined/edged with Sugru or another moldable silicone glue-like substance. Sugru is flexible, and you could apply it directly to the vat (if the vat has a thin layer of petroleum jelly to help release the Sugru when it dries), so the DIY cover will seal it perfectly. I’ve also considered a custom silicone mold, but that’s a lot more work.

Anyway I’ve had a few overly complicated ideas about it but Saran Wrap is working fine for now.

I use this and haven’t had a problem at all. This was recommended by a YouTube guy. I think it was Uncle Jesse.

3-IN-ONE - 120032 Multi-Purpose PTFE Lubricant, 4 OZ https://www.amazon.com/dp/B00J25JDDY/ref=cm_sw_r_cp_api_glt_i_3TR7N80V4CHWZRCYB41H?_encoding=UTF8&psc=1

For anyone in the US Trying to find one which isnt from CZ, i ordered one of these to see if it solves the problem.

https://www.amazon.com/dp/B01GC6VS8I?psc=1&smid=AA0YO4F2UD50F&ref_=chk_typ_imgToDp

I will be able to give updates tomorrow

You can use regular Elegoo Saturn sheets and they'll be fine.

I've been buying another brand on Amazon which work as well as the Elegoo brand and they're cheaper, and slightly larger too so there's a little more excess to trim.

This I found it on sale for like 22$ for a kilo

iForm 182 ABS-Like 3D Printer UV-Resin Rapid LCD UV-Curing Resin 405nm Standard Photopolymer Resin for LCD 3D Printer 1kg,Red Wax Color. https://smile.amazon.com/dp/B08L655QXX/ref=cm_sw_r_apan_glt_i_01MJVGMKQFKTCVCHX5RT?_encoding=UTF8&psc=1

Thanks - I do have a silicone pet food spill mat under the printer. Most of the resin spilled onto the pee pad, which worked as intended by keeping the spill confined. This is probably why it heated up - the resin concentrated and curing in one spot.

The silicone mat did its job and it was easy to cure/remove the resin. I have this one and if the spill had been contained to that, it would have been good.

I'll have to rethink what to use as a general protective layer beyond the silicone mat. The grow tent I'm using has a removable plastic coated floor tray and I may just put the silicone mat on that.

It will be fine. Resin printers have less issues with vibration since the motion is only in the up and down direction.

I would however recommend getting some disposable gloves and keeping a role of paper towels and isopropyl alcohol near the instrument. Resin spills happen and its best to be prepared for them. I also recommend getting a silicon mat to work over when handling the prints. You want one with a little lip of the outside incase you have a large spill so it stays contained. Something like this would work nicely.

ELEGOO Saturn S 3D Printer, MSLA UV Resin Printer with 9.1 inch 4K Monochrome LCD, Odor Reducing Facility, Speedy Printing and High Precision, 7.7x4.8x8.2 inch Larger Printing Size https://www.amazon.com/dp/B09NN8CS4L/ref=cm_sw_r_apan_glt_i_PEJ9NEP8ZFCNMTK5GT9Z?psc=1

Linear Polarization A4 Sheet Polarizer Educational Physics Polarized Filter Optical https://www.amazon.com/dp/B06XWXRB75/ref=cm_sw_r_apan_glt_i_HHASEPMKJ08TFMMMEQX4?_encoding=UTF8&psc=1

Just make sure you turn on the uv exposure on the printer and turn the film until most of the uv light is blocked. You will be able to tell once the light starts to block. Just pick the area it blocks the most then cut it to shape and tape down

For the most part, my machines get more "sticky" from pouring resin in or removing parts. Little drips here and there. I believe the FEP got a hole from a defect more than anything. I also got this flex build plate. Makes removing parts so easy plus I dont have to unscrew the platform more of the time.

Why not print both? The amount of time between printing one versus printing both won't change, but on the other hand you gain valuable insight and experience and can see for yourself which is better. At least, that's how I like to approach these things when I run into them. As for the supports, you can use light supports everywhere, but have heavy supports in a few spots around the model. Those will be your load bearing supports that prevent your model from falling off the plate. They can be clipped off with the flush cutters. The rest should come off easily in warm water if they are light. You can't avoid some joint marks but you'd be surprised how easily resin sands away.

I just got these and they work so well. I make the resin wet, rub the stick on the bumps a few times and they're completely gone.

[Sanding sticks]https://www.amazon.ca/dp/B07YG8Q6LD?ref=ppx_pop_mob_ap_share

I really like this stuff mixed at 30% with normal resin.

All of the comments you are getting is super helpful advice! I would also consider looking into a flex plate if I were you. Wham Bam Flex Plates are really good, but pricey. If you want a decent 3rd party one that seems to have pretty good reviews, does the same thing and for a fraction of the price- this is one I’m using.

You install a magnet onto your build plate- then a metal plate attaches onto the magnet and can be used as your New build plate. When you remove your prints, you simply flex the thin metal plate off. I will never ever print without one of these suckers again because I had the same issue as you with the insane sticking to the build plate.

I picked [this up](www.amazon.com/dp/B08QCJRD4J/ref=cm_sw_r_cp_api_glt_fabc_K1N7V1G5CSFCR1HYRRYD?_encoding=UTF8&amp;psc=1) last month and am happy with it! Reviews seem pretty good too which is what made me buy it along with its cheaper price.

https://www.amazon.com/gp/product/B00TA4B2Y0

plus

https://www.amazon.com/gp/product/B07BXBS93X

plus some shrink tubing, 9Vs, solder, and a wood burner (because I'm too ghetto to own a soldering iron). Solder isn't necessary if you get some teeny tiny crimp joiners... but I think it'll be stronger.

IIRC the phase matters so test with a battery in before you solder them together.

This is what I use, pricey but it works great. Haven't had to use my second one yet, but it gives great peace of mind, hasn't affected my prints at all.

The most cost effective solution tho would be using a spare FEP sheet and just keeping it on with painters tape, which is how I did it a few times and had no issues either. I just like the mach5ive better because it covers more area.

get the glass one you find on amazon, when ever you have accidentally cured resin spills in it you just need a wet rag and comes right off no problems.

ELEGOO ABS-Like 3D Printer Resin LCD UV-Curing Resin 405nm Standard Photopolymer Resin for LCD 3D Printing Translucent 1000g https://www.amazon.com/dp/B07PB7VCP6/ref=cm_sw_r_cp_api_glt_fabc_AZCDR3J9DB9HR49SYF6J?_encoding=UTF8&psc=1

Mach5ive Screen Saver- Clear Screen Protector for Resin 3D Printers - Universal Protection from Resin Spill, Internal, LCD Screen - Resin Resistant - Portable Protection - 2 Pack (Clear, Elegoo Saturn) https://www.amazon.com/dp/B096CJXCDL/ref=cm_sw_r_cp_api_glt_fabc_82K2B2E49B79ZQA6V3Q6

I'm using one of these digital temp controllers. Does the job for me. Has some great safety features too. Alarms when temps get too high or too low. Fire safety etc...

https://www.amazon.com/dp/B01HXM5UAC/ref=cm_sw_r_awdo_navT_g_TVGVYRD4D9HNPY19F4AM

I'm not trying to take it off completely. I read in this post that if there is any resistance, it's not a screen protector. So I tried to lift one of the corners ever so slightly to test that.

Thanks, I forgot to include it in the post - I ordered it from Amazon on Dec 2 and received it on Dec 3. Mine has the max fill line.

Glad to hear the bubbles won't affect printing! If it is a screen protector, then I am not worried. But I have never heard of or seen an LCD with bubbles underneath the polarizer. That's why I'm a little concerned haha

I just want to confirm - even if that is a factory-installed screen protector, should I still install another screen protector on top? Would that affect how much light passes through, thus affecting print quality? I'm asking because I already planned on buying Elegoo's FEP to place on top of the screen as an additional safety measure, but I'm not sure if the two layers would cause any problems. Eg. impact on print quality due to lower light transmitted, bed levelling issues, or anything regarding two FEP sheets touching repeatedly.

Also, out of curiosity, do I need to use Kapton tape (as opposed to something like transparent Scotch tape)? If so, why?

>I would very much suggest you also get Mercury X ~$180USD (https://www.amazon.com/ELEGOO-Mercury-Separate-Compatible-Printers/dp/B095K5LZY6) - the build-plate fits directly into the cleaning bucket unless you print directly from build-plate edge to edge.

In a similar situation as OP, and curious why the Mercury X over other wash and cure stations? Do the cheaper (~$100USD) ones not fit the Saturn plate? And do you just prefer two machines over one compared to the Anycubic W&C Plus (which seems to be in a similar price range)?

Thanks!

ELEGOO Saturn MSLA 3D Printer UV... https://www.amazon.com/dp/B086283SQJ?ref=ppx_pop_mob_ap_share

Yeah I believe so. I bought it back in September. If it is just a screen protector that would be great. Is there one you could link that's the correct size?

Washing is one thing but i'ts not hard to setup your own curing station box, a few searches on amazon come up with several UV light sources that are 395-400 nm sources and at least one 495-405 I've spotted, a couple of these in strip form lining hte inside of a large box would do the trick even without a turntable, with some creative glasswork (make sure it's not uv blocking) you could setup an easy all around curing box that gets the model top to bottom in one sitting,

Saturn wont work it is 24v 4amp, mars is 12v 4amp same as the mercury plus power adapter. You need a 12v 4amp minimum power supply I believe it is a 5.5x2.1mm dc jack. 12V 5A 60W AC Adapter Switching Power Supply with 5.5 X 2.1 mm DC Plug and 11 PCS DC Jack Connector for led Light Strips, Computer Monitor and More https://www.amazon.co.uk/dp/B07RZY52QN/ref=cm_sw_r_cp_api_glt_fabc_04Z6XP145R33CXRH00NV

Thank you... after taking a picture of the cable and zooming in close enough to count the pins (40) and then googling how to figure out the pitch (.5) I ordered these. And just in case this ever happens again I'll have 19 more of them. :/

Hard to say, typically you want fans that are more of a centrifugal fan blade (like those used in computer laptops rather than desktop PC), which can create higher static pressure. Personally I use this beast of a fan but its significantly strong than needed: https://www.amazon.ca/gp/product/B07JB292JC/ref=ppx\_yo\_dt\_b\_asin\_title\_o01\_s00?ie=UTF8&psc=1

What kind of resin are you using? Some smell stronger than others, but in my experience, at minimum you want to have an air purifier regardless (a decent one, there are many small/cheapo ones that won't do much. Spend at least $50-75 on one.

Putting holes in your cover shouldn't be an issue, since technically you could use the printer without the cover if you wanted (just keep it away from UV light). I would just be concerned with any type of air flow whether its being "sucked" out or even a light breeze possibly having effect on the resin.

Maybe I'm wrong and it wouldn't be an issue, but even if you do that, I think an air purifier is still necessary.

This is the one I have and it works great Air Purifier

I used the older version of this. Didn't change any of my print settings, still seems to work just fine.

Hey Im not sure if these are available for order/ship to the UK. But these are two I’ve used and recommend. First one I liked the most it was more stronger and just felt like it was working good. Plus it had two in the package lol.

1: Phrozen PFA (nFEP) Film (A4 Size, 210 X 297mm), Long-Lasting Uses- https://smile.amazon.com/dp/B08R3CZX71/ref=cm_sw_r_cp_api_glt_fabc_V6S5WX3XD7N8R853WMH6?_encoding=UTF8&psc=1

2: EPAX E10 X10 nFEP Film for 10.1" 3D Resin Printer, Size 295x210mm, One Film https://smile.amazon.com/dp/B08PQ4SCT3/ref=cm_sw_r_cp_api_glt_fabc_S9G1RJTH0R3J8R4AEXQW

ELEGOO Metal Resin Tank for ELEGOO Saturn 3D Printer, FEP Pre-Installed, with Lid and 3 Allen Wrench, Resin Vat for ELEGOO Saturn https://www.amazon.com/dp/B08NSL97F3/ref=cm_sw_r_apan_glt_fabc_1SAYSVGSR24QZMX8V4BP

Sold out, but there's the link

(1) I always put 2-3 drops of silicone lubricant on if the fep sheet has been emptied and cleaned, and I have never had failed print due to stuck on fep sheet: https://www.amazon.ca/dp/B07C3CZ9CL/ref=cm_sw_r_cp_api_glt_i_PGVJ4J0M2V20TWEABAHB (2) if you come from FDM world, be sure you are aware of “cupping” with resin printers when orienting your print. The mentality of how to orient a print on a lcd printer is completely different from FDM printer.

The Amazon link for the belt is in the caption for the first Pic. You could put a probe along the side of the vat. I would probably design something that could use the Thumb screw as anchor and hold probe on the edge I wouldn't let it just sit in tank. The ones that came with the temperature controller is waterproof so it could be sudmerged.Link for temp control https://www.amazon.com/dp/B08PFJR6JY/ref=cm_sw_r_cp_apa_glt_fabc_TH4D1TSJ2NG8C4J6Q7SN?_encoding=UTF8&psc=1 I don't see a need for the probe though the max temp of the belt is 45°c according to the probe. It is made to run for days at a time too. My plan is to preheat tank for a few hours and preheat resin bottle in warm water then pour into the vat and start print. My ambient temp is around 20°c so anything is better than that.

Good to hear! I use a iPad screen protector from Amazon: https://www.amazon.com/dp/B081VVMLRG/ref=cm_sw_r_cp_apa_glt_fabc_YC19NKB002WV86X7V6AP?_encoding=UTF8&psc=1

I've also used an extra fep but the screen protector is a cleaner install

I had bought a tie fighter lighting kit for a model a few months ago on Etsy (and to my knowledge no longer available but there are many like it on the site) but it didn't remotely do what I wanted for it. So it was off to a million different hobby Youtube sights and just buying way to many lighting kits on Amazon before I knew what I was doing. On the plus side I know now how to solder and want to put LEDS in EVERYTHING.

When I get home I will plow through my history and pull the entire list and link em here for you though.

Amazon had been out of stock for a while, but they recently got more. As I mentioned in my above comments, Ameralabs makes good (albeit stupid expensive) resin, and they sell their TGM-7 flexible resin on Amazon as well. As soon as they start selling AMD-3, I'm sure I'll be switching from Phrozen to AMD-3.

Tech Armor High Definition HD-Clear PET Film Screen Protector (Not Glass) for Apple iPad Air/Air 2 / New iPad 9.7 (2017) [2-Pack] https://www.amazon.com/dp/B00EL94Z4I/ref=cm_sw_r_cp_api_glt_fabc_P85HRXRJXCCFBBKK1JYN?_encoding=UTF8&psc=1

I switched to two-step washing, and it's made my washing station (Elegoo Mercury) IPA last forever. I bought these snap-tight food containers and filled the medium one about halfway with IPA. After printing, prints go into there and shaken around a bit before going into the wash station. This gets the most resin off before going into the washing station for final cleaning, and you don't need to worry as much about your first tub having dirty IPA because the washing station will take care of that.

Maybe when run out of the 4 gallons of IPA I bought, I'll check out water-washable, though. I'd like to at least do a comparison.

Available on Amazon US as well now with a limited time $20 coupon to bring the price down a bit, still not as good as that early bird price :)

https://www.amazon.com/gp/product/B08YVV7V7G/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

I just got a standard exhaust hood that is large enough to sit behind the Saturn and it works great. Not as bespoke but it handles the fumes perfectly

POWERTEC 70169 Mini Gulp Dust Hood with 4" Port, 13-1/2" x 7-1/4" https://www.amazon.com/dp/B01EY1NCM8/ref=cm_sw_r_cp_api_glt_i_PJQHAC9N2073Q41KZDMF

I got the small and it fits perfectly. I also got a upgraded temperature controller so I could get alerts if the temps went out of range and power off the unit from my phone.

https://www.amazon.com/gp/product/B08L2ZC6BJ/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Yeah! I have a metal chemistry cabinet that I put the printer in. I sealed it up with 1/2 inch thick pink foam from Home Depot. I then installed the components below, with the bulb hanging from a light socket above. I run the cabinet at 85f and have no failures as a result. All of my paranoia about resin printing has been solved.

The heat bulb needs to be about 6 inch away from everything so it doesn’t, say, soften the cover to the printer. I think there is prob a better solution than this hot bulb though. Maybe just a tiny space heater with a legit thermostat on it.

Honestly, if I’d do it again, probably a big fish tank heater sealed into a 1 gallon vlasic jar full of water. That would retain residual and even heat even as you open the door and the warm air rushes out.

This is the same build parts and quality of the S400s with mono screen and mainboard. The S400s has a lot of poor reviews of its build quality. The Saturn to its credit has only 1 poor review (out of 107) of its print quality which was probably due to the operator anyway.

I have the same container and I think it tapers a bit, but the build plate still fits and sits nicely on the bottom.

That said, I've also ordered this one, a shorter version with the same dimensions Lock & Lock 54oz. Since I have a flexible plate setup, and I plan on detaching the plate, dropping the prints into the larger container, and then placing the actual platform into the shorter bin.

That's not the same printer (Combat model, not Colum, different buildplate, etc.)

But yes, Lychee and CTB work.

The thing is barely out and most people still can't get it. So it'll take time to develop accessories. That said this blackout cover fits over my Saturn. This one is not available right now but there might be others like it. https://smile.amazon.com/dp/B07Y3WVDJC/ref=cm_sw_r_cp_apa_i_BAD-Fb26VV5ZN?_encoding=UTF8&psc=1

Are you in the US? I just got mine today from Amazon, ordered it Thursday. Amazon was releasing them in spurts of a few at a time throughout the day, and they sold out each time almost immediately. I even got one in my cart once but it disappeared before I could check out. I eventually snagged one. I don't know if they've been adding them since Thursday, since I stopped looking. It won't show up in an Amazon search, so use this link. Keep it open and refresh it occasionally. https://smile.amazon.com/gp/product/B086283SQJ/

Nice temporary solution. I have one of these silicone pet food mats under mine. Cheaper than the ones being marketed for resin printers

https://smile.amazon.com/gp/product/B07SYC8PLK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Dimples and such are normal, that should not need to be replaced. Unless they're really bad and about to rip or something extreme.

For replacements, I think you might be able to use:

https://www.amazon.com/dp/B085J2W3JN/

cut in half. I haven't needed to replace my FEP yet on the Saturn, but the dimensions seem to work out. That would be 8 replacements with free shipping, so just $3.75 per sheet.