What are

/r/klippers'

favorite Products & Services?

From 3.5 billion Reddit comments

The most popular Products mentioned in /r/klippers:

The most popular Services mentioned in /r/klippers:

hastebin

Loom

WireGuard

ZeroTier

Home-Assistant.io

Orange Pi

Autodesk Tinkercad

ImgPile

Docker

Codeshare

Git Bash

Cyberduck

The most popular reviews in /r/klippers:

First off, many of the silicon spacer kits come with one shorter than the others for this exact reason. If none of yours do I'd try to just cut a bit off of one with a tube cutter, or something similar that can make a flush cut.

As for the rest, you're mixing a few different topics together but make sure the coordinate positions of each screw and the screw_thread (probably CW-M4) is correct. Look over the Klipper documentation for proper usage. For manual testing with the nozzle you'd want to use the [bed_screws] config section and BED_SCREWS_ADJUST command instead of the [screws_tilt_adjust] section used with the probe.

Using the center of the bed for the Z offset is fine but clear any bed mesh that might be saved before running it.

The way to really know what's going on is to grab a decent dial indicator gauge (something like this) then mount it to the print head. You can likely get away with even cheaper versions that are accurate enough for this.

That will show exactly how much it varies compared to the mesh visualizer. However any movement in the axis will also show up this way. To measure only the bed, you'd attach it to a base with an arm.

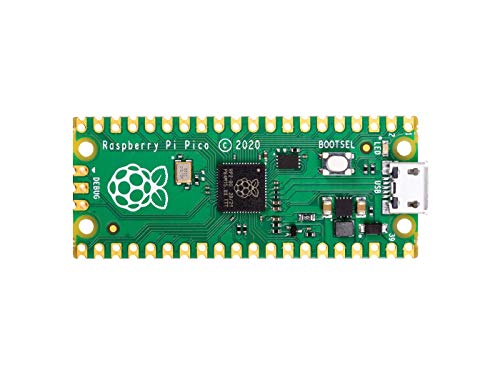

Basically the same way you do with a Pico, as many STM32 chips will also work with the USB-CANbus bridge firmwares.

It still requires a transceiver as these boards were not designed for CAN and don't include the appropriate hardware for transceiving the CAN signal.

But those are cheap and easy to get.

Beyond that it's just crimping some cables and configuring/flashing your firmware for CANbridge mode.

Sure!

Mine is heavily (i.e., pretty much entirely) based from the stock config for the 3v2 provided with Klipper: https://github.com/KevinOConnor/klipper/blob/master/config/printer-creality-ender3-v2-2020.cfg

That worked pretty much perfectly for me as a starting point, though I did do all the PID calibration for the bed and hot end, and unsurprisingly the numbers changed vs. the stock Klipper config (I guess that's normal and varies from printer to printer anyway).

The other changes you'll see enable BLtouch, calibrate my e-steps, calibrate pressure advance, calibrate heaters and enable arc support (for Arc Welder, definitely recommended) plus configure the bed mesh (which I tend to recalibrate every week or so, I left the actual mesh in the file so you can see it even though it'll be pretty useless on any other printer)

All in all, probably a day or two of tweaking and fiddling, but totally worth it imho

Yeah, that's what happens for X with really light print head (stock). I assume Y would be much worse.

And here is what happens with BMG+v6+stock stepper direct drive. Quite a bit different...

Good, something was probably loose or slipping. With your setup you may also want to consider using anti-backlash nuts. Brass versions are more common but I've found the POM nuts to be far superior at minimizing backlash.

Usually not necessary on the ender but with dual Z and a volume that wide, I'd want to minimize any bit of movement.

No, I didn't. Went smoothly for me.

If it helps this is the exact one I purchased.

https://www.amazon.com/gp/product/B07DMZCGP9/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

Are you confusing thermistor and heater cartridge? Thermistors don’t have a voltage rating. And most of them measure around 100k ohm at room temp. The heaters have a voltage rating, 12 or 24 depending on your system supply voltage for your printer, and a wattage rating, usually around 40 watts.

The volcano hot end should work with any of the common cartridge style thermistors. The heater is also a cartridge, but somewhat bigger.

The thermistor will normally say something like it’s a 100k thermistor and have a number or suck for the type. Each type has a different temp vs resistance curve, so that’s why you need the type to match.

I’m not using klipper yet, so I don’t know how they do it in the config file, but for marlin firmware there is a table of common types and you set the index of the one you have.

Here is a link to a common thermistor for volcano hot end on Amazon. It’s a type 3950.

Okie dokie I got it to at least show me what the hell it’s doing. I set my max temp to 10,000c and my min to -250c and now it’s showing data. HOWEVER It is reading at -40c for reasons I cannot fathom. This is my thermistor: 1piece 3D Printer 500℃ Thermistor... https://www.amazon.com/dp/B0888NJ63W?ref=ppx_pop_mob_ap_share

And this is a “review” of the thermistor. I put this in my config but it didn’t do anything.

“after calibrating this to a known thermistor it now accurately reads from 200c-350c I can't speak for anything higher as I don't have anything else that reads that high. I will update the review if I can confirm temps up to 500c but i suspect it will read just fine at those temps with the config bellow

[thermistor T-D500] temperature1: 200 resistance1: 8900 temperature2: 275 resistance2: 2250 temperature3: 350 resistance3: 785”

Yes using the gpio pins on the pi is possible.

But in your case it's not a complete solution. You can't just wire up a fan to the pi and be done.

You will need some kind of mosfet to control the fan, or 3+ pin PWM fans that have a 3rd pin for control.

I've had success using cheap mosfet boards like this to allow my pi/etc to control standard 2-pin fans with a GPIO pin.

Yeah, at least now you have a game-plan for diagnosing it.

And again, replacing those endstops is really inexpensive and easy if you want the peace-of-mind (or later find yourself with no choice)

Here's a full set with cables for $8 (even with the Amazon tax)

I'm sure you could pay far less if you were willing to wait for longer shipping or shop around.

You'll want this open barrel crimper for starters.

BLTouch: Crimping connectors as small as the BLTouch's requires special tools and a different crimper, so I just re-terminate the cables, extend, or buy a new one.

Steppers: The steppers use 6 pin JST PH 2.0 on the stepper end and 4 pin JST XH 2.54 on the board side. It looks like this kit has both.

Lastly, you'll want 24awg stranded wire for the steppers.

Endstops use JST XH on both ends, so the kit will let you do those, too.

Gotcha. There are a couple approaches, in increasing time/difficulty:

- Cable extensions: these are JST XH 1m extensions you can get in 3-4 packs on Amazon. Quick and dirty and also extend your endstops.

- New cables: buy replacements that are 1m long (doesn't work if you need more than 1m, like the extruder).

- Splice: Cable 1 + cable 2 + some soldering and heatshrink = longer cable 1

- Make your own: this is the hardest but super rewarding in the end. You'll need lots of wire (mostly 24awg), connector kits, patience, and practice. I make these in my free time as a hobby.

Documenting making a wiring harness is an open area of interest for me. Some of the next versions of OmniBox will include suggested pinouts for panel mounted connectors on the case (JST SM and Molex Micro Fit 3).

Lastly, if you splice or make your own, make sure to test the connections with a multimeter.

That heater is essentially the same power and voltage as the stock heater (at least on my 3v2) so no you don’t need to worry about a thermal fuse or extra grounding. Probably don’t even need an upgraded mosfet to control the heater, depending on your control board.

If you go to a line voltage heater with like 500W or higher, then you definitely need both the thermal fuse and the upgraded grounding.

One thing I suggest, get some stick on foil faced foam insulation and put it over the bottom of the heater and bed. It will save power since you loose as much heat off the bottom as the top, and keep the whole bed at a nice constant temp. I’m using this from Amazon

https://smile.amazon.com/gp/product/B07VWLHPSS/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Might as well do it while you have the bed off.

Thank you! It's been pretty fun designing and building it. My first real project is of course upgrading the printer itself, lol.

I put the Pi4 in this enclosure kit. I also upgraded the fan to a 3 wire one with leds in it that's setup with a temperture_fan control to automatically turn it on and of per the Pi's CPU temp.

Then designed the printer mount for the Pi to use two existing screws to hang on the side and the Pi enclosure just slides in from the back up to a stop that lines up a slot for the USB C power cord to plug in. It also puts the back end right next to the USB C port on the printer, which works well for a super short 3" cable.

The PiTFT50 is mounted in a modified version of one I downloaded (they actually included STEP files I could use in SolidWorks) but can't find the link now. I had to modify it quite a bit though just to get the screen to fit right. The ribbon slot was on the wrong side and the front cover wasn't centered over the screen well enough. I made the bottom thicker for 3 brass inserts which line up with holes on the adapter piece I designed to mount where the stock screen mounts. That part was probably the trickiest one to model, but it works pretty well.

I do have solid models as well as STL files, but this is still a bit of a work in progress. Eventually I'll have to take the time to put it all together on thingiverse and/or printables, but I haven't gotten that far yet. Still building and tweaking things. Now I just ordered a 1080p Arducam with IR lights, so I'll soon be busy designing and printing a new mount for that. It uses a USB cord, so I may modify the camera arm some more as well.

I have an earlier version of the corner piece without the camera mount on it too. Saved that as a separate version for anyone not wanting to mount a camera there.

> First, would a touchscreen such as this one (https://www.amazon.com/SunFounder-Raspberry-Touchscreen-1024×600-Capacitive/dp/B07Y889J3X/), work with touchscreen despite not being used with a Pi for KlipperScreen?

Yup, any HDMI touchscreen should work fine. Keep in mind that USB is also required, both for power and the touch interface

The flat plane being above the mesh isn’t an error. Mine looks like this too.

Does the profile look like this every time you run it, or does it change frequently? If it looks similar each time, your bed is probably warped. In that case I’d recommend buying a glass bed. This creality one is $18, but you can find cheaper ones if you’re trying to keep your budget low

https://www.amazon.com/Creality-Upgraded-Printer-Tempered-235x235x4mm/dp/B08CXLLCH4/

If the mesh profile changes very frequently, you probably have a loose bed or x gantry. Both can be solved by adjusting the eccentric nuts

If your thinking of upgrading the Extruder, I got this one that’s a BMG clone. Works like a champ! There is a slightly cheaper version if you don’t want the coated drive gears, but I figured just do it once and be done.

https://www.amazon.com/gp/product/B09HL83GXN/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

If you want cheap, the red metal ones from Redrex and BigTreeTech also work will, but don’t have the gear reduction, though they do apply more torque than the stock one due to the use of the grooved drive rollers.

So the good news is - I have another printer so making an adaptor is easy (from the pics it looks like my smaller resin printer will do the job) I'll definitely consider that, but of course - I'd much ratehr upgrade for features than "just to make it work", and if the issue is the pi400 being too weak, then that's an issue.

As for the sd-card, that's a brand new phillips. https://www.amazon.nl/gp/product/B00FEFFVRI/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

I literally bought it 3 days ago. I'd be very pissed if that card is already giving issues. But I do have another 8Gb - which in theory is significantly worse, and I got all my configs backed up to github, so trying a different card is, at least, a quick and easy test

There are many types of lubricants you can use on leadscrews, and everyone has different preferences.

I use SuperLube, and a lot of people in /r/3dprinting will recommend it too. You can find it at pretty much any hardware store, and one tube of it will last forever. White lithium grease works fine too, but I find that Superlube is a bit longer lasting and less messy

This is what I'm referring to. The same brand sells o-ring lubricants/etc that you do not want: https://www.amazon.com/Super-Lube-21030-Synthetic-Multi-Purpose-Grease/dp/B0B2MLNP65

Aside: this the pico board you mentioned ? https://www.amazon.nl/-/en/dp/B09VL3MM5V/ref=sr_1_1?crid=19YFXZNRU9Z3U&keywords=skr%2Bpico%2Bbord&qid=1667033195&qu=eyJxc2MiOiIyLjAwIiwicXNhIjoiMC4wMCIsInFzcCI6IjAuMDAifQ%3D%3D&sprefix=skr%2Bpico%2Bboard%2Caps%2C64&sr=8-1&th=1 because it's a significant saving (more than enough to make up for the cost of a crimper and a set of crimps)

I defo don't have the skills, equipment or time for a manual repair. Shame though, I was printing perfectly fine just a week ago. Well I'm happy the motherboard held out for this long.

Sadly I moved too many times where I lost the creality board the ender 3 came with, so that's a no-go.

Good thing is I just got paid, so I'll look into buying a new board.

The SKR Mini E3 V3 is a bit cheaper than the V2.

Do you think I should upgrade to that?

I remember hearing that configuring the firmware is a bit different, but I don't think klipper has problems with it right?

I had this problem when I first installed Klipper and flashed the firmware. It went away when I removed the red wire (+5V) from my USB cable to keep the Pi from powering the mainboard. If you don't want to slice cables up and potentially have to solder them, something like this should do the same thing:

I went with a Pi4b for 150, PiTFT50 for 55. $205 total to not have a crippled system without SSH. I haven't actually used a Sonic Pad, but the "modified" older version of Klipper and Fluidd sounds sketchy. Kinda like their "modified" Marlin that for some reason was missing certain gcodes.

I think people can still load different printer config files and get it to work with models other than the Ender 3 family, but it's still a crippled system and $170 (just checked the price on Amazon) is not exactly cheap.

Here's the pitch...

>🏆【Get It Going with No Hitch】:Creality Sonic Pad can connect to almost any FDM 3D printer on the market via a USB cable. With the included configuration manual, it is easy to set things up. Besides, it has been pre-configured for Ender-3 V2. eNDER-3 s1, and Ender-3 S1 Pro, so you can get it going in seconds.

Are you sure that your buzzer is capable of changing pitch?

The first buzzer I tried this with behaved a lot like you are describing.

​

>Next step will be to move the beeper to my SKR MCU PMW port and see if it makes any difference.

You could try it.

By default Klipper uses software pwm so it doesn't matter what pin you use. However, if you are going to try a hardware pwm pin, you could try setting hardware_pwm: True in your [output_pin] config.

FWIW I have used these speakers and can confirm that they work properly with Klipper and changing the tone/frequency of the beep.

These are what I ended up buying ages ago. They're still just fine:

https://www.amazon.com/gp/product/B08FJ6ZVH8/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

I am currently using a stock hot end with an all metal heatbreak with a shallow bowden tube and a ceramic 115w volcano heater block (CHC PRO Kit). Keep in mind the price for the CHC includes heater block, nozzle, heater, thermistor and sock. It was going to cost more to source volcano parts separately and it wouldn't heat as good. Just make sure your heater wiring is sufficient for 115 watts. The housing is custom with twin 5015 blowers. I am trying to maximize throughput. I like the heatbreak with a flat for the set screw to land on so I can tighten the nozzle when it inevitably oozes. I am pushing very high extruder pressures.

I purchased a MicroSwiss a long time ago and I regret it to this day. It is nothing more than a stock hot end with an all metal heatbreak, just buy shallow a heatbreak for a few dollars. I can never get it tightened correctly, it is always oozing molten filament and the nozzle comes loose no matter how tight it is against the heatbreak. I don't want to waste my time and money on finicky/overpriced parts.

This is what I am currently using, you can get these from Alibaba for a about a dollar.

https://www.amazon.com/dp/B09V46R7YR?psc=1&ref=ppx\_yo2ov\_dt\_b\_product\_details

No, i2c interfaces don't have sufficient throughput to use the accelerometer for resonance testing.

Yes, i2c can be used in Klipper, but not for this purpose.

My advice would be to get a pico, configure it as a secondary mcu, and use its SPI pins for your accelerometer. That discourse thread has a really great overview/walkthrough of setting that up.

You can potentially even use its two SPI busses to host multiple accelerometers. Or you could just set up one and move it between measurements.

The process only really needs to be done once as long as you don't change anything that would affect the resonance profile. After measuring, the accelerometer doesn't do anything so there's really no reason to even keep it mounted/connected.

Additionally, regardless of how you choose to do your wiring/measurement, choosing to go with a pico will give you plenty of pins to use for other purposes, making up for your lack of pins on the host system. Plus the RP2040 is a really flexible chip that can do fancy things like host a CANbus network. In many ways it's more capable than a raspberry pi when it comes to its gpio.

JST is a brand, the type of connector used on the stepper motor side of that cable is JST-XH. Your message also didn't really clear things up for me too much, but it sounds like you just want to buy some JST-XH connectors, for six wires, in a male-female pair, or just buy one of those variety pack boxes that has a bunch of different sizes of them? You linked something you'd bought, but that one has pre-crimped cables included, while you want loose connectors so you can crimp your own cables, so, something like this: https://www.amazon.com/460PCS-XH2-54-Connector-Terminal-Connectors/dp/B09DBGVX5C

If you don't already have a crimping tool for this, IWISS makes good budget-friendly crimping tools. For a task like this, you'd probably be good with their IWS-2820M (28 - 20 AWG wire size). For thicker wires, IWS-2412M (24 - 12).

You can use a non-touch display with a set of buttons or a rotary encoder.

Like this. This is wired to your mcu and configured in your printer.cfg

Or if you would like a touchscreen, you can either use an Android device via KlipperScreen or connect a HDMI touchscreen to your host.

It doesn't need to be a raspberry pi to use a HDMI touchscreen. The screen will connect to your host via the HDMI port (for video) and a USB port (for touch controls and power)

The only option you can't really use without a raspberry pi is displays that are designed to use the pi's ribbon display connector. Any device with an HDMI port should work with an HDMI display. BigTreeTech also sells HDMI touchscreens for fairly reasonable prices.

>but you’ll also need to connect the negative of the PSU to the GND of the Pi otherwise you can run in to floating ground issues

This.

It's very important to tie the grounds between all your components regardless of what voltage they use. If you do not connect the ground pin to the pi in addition to connecting it to the psu, it will not work properly, or possible not work at all.

​

>I believe you need a level converter if you are connecting the strip direct to the pi

Maybe.

It really depends on your strips and how long your wires are, your soldering/crimping, etc.

I've never had a need personally, outside of huge installations like Xmas lights.

Alternatively you can use a "sacrificial LED" as a level shifter by wiring an extra LED halfway between the strip and the pi.

The reason this can be an issue is because LEDs expect/prefer a 5V data signal. The pi uses 3.3V for its data signals.

Typically components are tolerant to a range. A device which expects a 5V signal will work with something like 3V-7V (I don't know the exact values) but 3.3V is right near the bottom end of what the LEDs can work with.

This becomes a problem when your LEDs are connected to the pi over a long wire because of voltage drop. If the pi used a 5V data signal there would be plenty of room for long wires because the voltage drop would have to drop a couple of full Volts before it becomes a problem.

With a 3.3V signal though, only a short length or poorly soldered wire can be enough to drop the data voltage below what the LEDs can work with.

A level shifter or sacrificial LED will bring the voltage back up to 5V correcting this issue for any subsequent LEDs.

If you want to purchase a level shifter for this rather than use a sacrificial LED, I've had success with chips like these

The hot-glue on the connectors can be easily removed with a little isopropyl alcohol. You can easily remove those connectors without damaging them. I wish I had known that when I did mine slowly and carefully by cutting the glue off lol.

Otherwise, the connectors are all JST-XH.

You can use a kit like this to make your own/replacement cables for those connectors. There are also some kits that come with a crimping tool.

Personally, I use and recommend buying an IWISS IWS-320M crimping tool separately.

This tool works much better than the ones typically included with kits ime and it's been able to successfully crimp all of the different connectors I have used, not just JST.

Anyway, that said, you shouldn't need to do any crimping. You can remove the current connectors with a little alcohol and they will fit on the new board as they are.

>Do you know what the insulation is that's already under the bed?

I don't, my bed didn't come with any insulation.

But I found this with a quick Amazon search. Says it's good up to 150°

That would work fine I imagine.

Yup!

The only additional hardware I bought besides the SKR-Pico and EBB was one of these little guys.

Just wire it up and configure as described in my guide and the SKR-Pico will do double-duty as both a Klipper board and a CANbus bridge that can host the EBB.

Then by using the EBB for the extruder driver you'll have an extra driver on the SKR-Pico that can be used for [stepper_z1]

Yup! And a lot of people already own Pico's for that exact reason!

​

>I bought some rp2040 boards which have typeC connector, ws2812 onboard, and it's cheaper than raspberry pi pico.

I love these cute little guys!

Is that what you are referring to?

They are my preferred picos as well, at least when I don't need an excessive number of pins.

That said, ime they are a little bit more expensive than the classic pi pico's and they do have less pins available to utilize so if you intend to connect a lot of components that can't share pins then the classic pi pico might be a better fit.

Probably won't be easy to replace the mosfet on the board. You could potentially get a mosfet and control it from a free I/O pin if you have any on the board. You could use something like this (though I'm not necessarily suggesting this particular one): mosfet

Yeah I just use a Waveshare CANhat on my pi.

But it's not perfect.

Not everyone has a pi (or soc with equivalent gpio headers) to use in the first place, and it takes over the UART pins (and a couple others) so you can't use it alongside another UART device.

I'm content with using the hat (and connecting my other mcu's via usb) but there are also usb CANbus adapters available.

From what I understand though, using a pico just seems to be a slightly cheaper DIY alternative. It doesn't have any specific advantages (that I'm aware of) over other more traditional methods.

Maybe I just don't know about them, but I didn't seem any compelling evidence that a pico is a superior solution.

That said, being that it's open-source maybe it will grow, and the necessary components (a pico and a CAN transceiver) are not at all expensive.

Actually I think I've convinced myself, I might pick up some of those transceiver chips and give it a go haha.

What did you find to be underpowered about it?

It could be worm rollers but unless they'r'e flat on one side and locking up, you're going to have a hard time stopping that stepper moving outright without some sort of noise.

The arm of the extruder - the part the spring pushes against, breaks easily. Most of us have replaced it at one point or another.

I strong suggest you don't buy the same extruder just dual gear. It's just not great in any incarnation.Look into the BMG clones on amazon. Shouldn't be more than $15. They're dual gear, plastic body but don't let that bother you. The highest end printers run BMG extruders. I bought one for like $13 thinking, well if it sucks its only $13 and ended up loving it. It's perfect and is made to work with many, many types of hotends so you're good long term.

Just my .02 cents

hope you sort it out!

Thanks man, you are the best. I added a small low RPM 80mm silent fan inside the enclosure just on my workbench, circulating down the side of my printer base and the temp is already creeping up. Will continue to work on this, though I do not want to "throw a blanket over it" :). Potential for lining it in reflective tape though. Problem there is it messes with the lighting, and the cameras, etc.

What about a liner on the outside white part?

I also have a temperate pad from home brewing I was considering using: https://www.amazon.com/Northern-Brewer-FermoTemp-Fermentation-Temperature/dp/B01MY7TAWQ/ref=sr_1_6

This is fairly low temp, would placing this on or under my marble stone assist do you think?

I bought a cheap-ass usb webcam and it works great.

I paid $20 for it at the time, but it seems to have gone up a little on Amazon

It's basically just plug and play.

You can configure it from the Mainsail/Fluidd interface but ime the defaults work fine.

Yeah some people use a phone or a raspberry pi camera.

But if you want easy: a generic usb webcam is basically foolproof.

This was asked by someone else quite recently - https://www.reddit.com/r/klippers/comments/vmv0z5/restart_print_after_power_outage/

The short answer is no, Klipper doesn't have any power loss protection. The recommended way to protect against power loss is to connect your printer and Pi to a Uninterrutpable Power Supply (UPS). This is the one I use with my printer - https://www.amazon.com/APC-Battery-Protector-Back-UPS-BE600M1/dp/B01FWAZEIU/ It will protect your printer from stopping during a brief outage or blip, but don't expect it to run your printer for more than 10-20 minutes after the power has gone out. You'd need a much higher capacity unit if you're frequently having multi-hour outages.

It turned out to be a faulty thermistor. Not sure if I can link here but I ordered these and have had the printer back up and running since. The don’t entirely fit into the heat block, since the stock spider thermistor has wires going into the end of the actual tube, whereas these have a crimped end with wires coming from that. Additionally, the wire is about 6 inches too short, so I extended it with some of the old thermistor wire. I pushed it in as far as I could up to the crimped section, and redid my PID tune, being sure to save the old values in a text document in case the new ones were wildly different. The new tune values came back almost the same as the old, so I went with those. Probably put about 150 hours on the printer since, and have had zero issues.

In hindsight there is probably a better fitting probe you could order. These are an NTC100k 15x3mm (if my memory is correct). Let me know if this helps!

It has 3 controllable fan outputs, but I believe they are whatever voltage your power supply is. So you would need a buck converter to drop it to 12V. The other option is just an external power supply, if you aren't comfortable soldering. Something like this has screw connector adapter...

> Because I already have them.

There certainly is logic to this, but that doesn't mean it is the best choice. It might be, but I would recommend you at least consider the alternatives.

For example for $26, you could get these LEDs, which are drop in compatible with the SKR Mini, and give you full RGBW capabilities. If all you want to do is light up your printer, you only need white, but adding color lets you use the leds for signalling, also.

I love JST-XH connectors! I use them in all my hand-soldered projects!

Most printer boards use them as well, or the slightly smaller JST-ZH, but don't get these, they don't fit standard 2.5mm pitch pins so they are pretty useless unless you have a custom pcb.

The only flaw JST-XH have is they are only for "wire to PCB" not "wire to wire"

For "wire-to-wire" I like JST-SM connectors but I haven't really tried much else so I don't have a lot to compare to. These are also common in printers.

Open to any other suggestions though!

I was always using DuPont connectors, even crimping them myself.

I don't know why it took me so long as I was already using them for other projects, but it recently occurred to me that you can just as easily use JST-XH connectors in place of them.

First and foremost because they are much more secure, they actually clip in place.

But they are also more low-profile and imo easier to crimp successfully.

I never really felt good about using DuPont connectors, especially the single-use variety, and especially on components that are going to be moving.

Also if your headers are already soldered on to the ADXL (or whatever component) you can pull the pins out of a pcb-mount connector with pliers (so it's just the white plastic remaining) and then slide it onto the header and use the header as the pins. That way you can change from DuPont style to JST without having to desolder anything or replace the component.

Anyway, just a thought!

Figured it was worth sharing in case anyone else hasn't thought to do the same.

I recommend aiming for something with a Mediatek chipset, as they're usually better supported...

If you're after long range or high speed with the Pi, and don't mind having to custom build a driver, I have this TP-Link Archer T9UH with the Realtek RTL8814au chipset. It needs this driver, which I was able to build by following the instructions on that page. It works like a champ, until there's a new kernel release, in which case it breaks until I rebuild that driver. It does however offer USB3 and 11ac, and has no trouble connecting and maintaining a high speed link (100+mbps) between where it lives in my RV parked in the driveway, and the AP in the back bedroom of my house. This is enough distance where the onboard Pi4 wifi could barely see my network and couldn't even sustain megabit speeds reliably.

I have one of these available. Could I wipe it, put Linux on it, and make this work? (Amazon link below)

AIEX 8pcs 3D Printer Heat Bed Leveling Parts, Solid Heat Bed Silicone Leveling Column Replacement Spring Heat Resistant 3D Printer Solid Bed Mounts for for CR-10 Ender 3 (0.63/0.7 Inch, Black) https://www.amazon.com/dp/B09M6SD9KQ/ref=cm_sw_r_apan_i_92C0M5C7VF30GAQD6BSH?_encoding=UTF8&psc=1 use the longer ones.

I have one of these printers with that board and it does not expose any SPI pins.

As far as I'm aware you can't even solder onto the legs of the chip like you can with UART. There just isn't access to SPI, period.

Fortunately a pico is less than $10 on Amazon and has plenty of SPI available! I'd suggest picking one of those up and using it as an additional mcu to host the adxl. You can connect it to your host system via usb and it will give you access to SPI, i2C, and any other GPIO components you might wish to use. Temperature/humidity sensors for example.

I ordered this one in the UK, not sure where in the EU you are but check amazon

I do recall that I had a similar issue also, it turned out that the adxl board was crappy. (The ones I ordered were these.) To troubleshoot/determine that it was the adxl board, I downloaded some basic code to test the adxl - something like this. Do remember that other testing code may have a different physical connection between adxl <-> arduino, so if it tests satisfactory, ensure wires are correct before using with klipper. Also to note, that particular board liked 5v, and didn't want to play nice with 3.3v - even though it said it would. In the end I also soldered wires directly from another adxl and the arduino and it worked.

Good luck!

I am using a this https://www.amazon.de/dp/B08C5GDG9Q/ref=cm_sw_r_apan_i_K4FT99K3BBDVDPGEF79R?_encoding=UTF8&psc=1

And I trend changing the things you suggested. Sadly still not getting an 8mage. I know the camera is working because it has night vision that makes a kliking noise wen activated.

The left stepper is the one that came with the ender. The right one came with this (42-34 stepper motor) kit: https://www.amazon.com/gp/product/B08RJDW5W6/ref=ppx_yo_dt_b_search_asin_title

How do I test that they have the same force?

[stepper_z]

step_pin: PA15

dir_pin: PA8 # this is inverted withOUT the "!" for SKR versus from the stock board

enable_pin: !PD1

microsteps: 16

rotation_distance: 8

endstop_pin: probe:z_virtual_endstop # ^PC0

position_max: 215

position_min: -3

homing_speed: 20

[tmc2209 stepper_z]

uart_pin: PD0

run_current: 0.600

hold_current: 0.400

diag_pin:

stealthchop_threshold: 999999

[stepper_z1]

step_pin: PD11

dir_pin: PD10

enable_pin: !PD13

microsteps: 16

rotation_distance: 8

[tmc2209 stepper_z1]

uart_pin: PD12

run_current: 0.600

hold_current: 0.400

diag_pin:

stealthchop_threshold: 999999

> What camera

Literally the cheapest I could find on Amazon

As to the specific settings, it's gonna vary depending on how your strips are installed, how many LEDs, and the type of LEDs.

In my case I used pretty densely packed strips and I was able to fit a strip with 5 individual SK6812 LEDs on my hotend so I disable number 2 and number 4 and have 1,3,5 pretty dim. It's easy to play around with in the WLED web interface and set up the colors and animations you want for a preset. Then you save it on the WLED interface and make note of the preset number/index.

Then just follow the moonraker docs to set it up as a lighting device and create the base macros.

You can then use something like:

WLED_ON STRIP=tool PRESET=7

in your gcode to tell moonraker to tell WLED to activate that preset. The other advantage over directly attached LED strips is you can run as many or as complex animations as you like and they won't hold up your gcode because they are processed separately.

Directly-attached strips can't really do animations during printing because gcode can only process a single command/thread at a time so any animation would hang the print until the animation completed. WLED doesn't have that problem, all you need is a super inexpensive ESP8266 or ESP32 to control it.

They are colloquially called DuPont connectors. Though that's a brand name and I think there's actually a technical name but I dunno what it is.

If you call them DuPont connectors people/search engines will know what you're talking about.

I'm going to assume you don't have a tool to crimp them either, do I would recommend a kit like this

That said, they are kind of a pain in the ass to crimp well in my opinion and I prefer just soldering the wires. Besides if your ADXL chip doesn't have headers either you'll either be soldering the headers and crimping the connectors or just soldering the wires directly.

I tried a few before settling with this. Been printing about 20-30 hours with it and no errors so far.

https://www.amazon.it/dp/B00RX1H9ZS/ref=cm_sw_r_apan_i_G8NK6K420KASFG40JK9X?_encoding=UTF8&psc=1

Holy hell you're totally right, I dunno how I mixed that up.

I went as far as to google the i2c address of the chip I was using before finally going to look at it physically on my printer and.. it's not a fucking DHT22, its labeled GY-21 and it's one definitely an SHT21 chip. I had switched it out at some point after initially trying to get a real DHT22 chip working and giving up, and then apparently completely blacked it out. In my defense, they all have very similar sounding names and I had been running on little sleep.

Man I feel like an asshole now. I will go back and edit my previous comment.

I apologize to anyone I misled, DHT22 chips don't work with Klipper, at least as far as I'm aware. There are a lot of inexpensive alternatives such as this one though.

>I thought I would miss the screen, I don’t.

KlipperScreen is also way better than the stock screen if you pick up or already have a small (or not-so-small) touchscreen display.

So if you find yourself missing having a display on the printer still, you'll be way happier with KlipperScreen that you ever will with the stock display. I love mine!

Back when I was big into building mechanical keyboards I did a lot of research on vibration dampening.

The best material I have ever seen for this purpose is sorbothane.

It can be kinda pricey if you are looking for a big slab of the stuff, but I had significant, noticeable improvement from sticking these sorbothane hemispheres onto the feet of my printer. Made a really big difference, even compared to the TPU printed ones I made.

I bought this from amazon:

4PCS GY-291 ADXL345 3-Axis Digital Acceleration of Gravity Tilt Module IIC/SPI Transmission for Arduino https://www.amazon.com/dp/B094NHTPKR/ref=cm_sw_r_cp_api_i_0T48MHE8TCA7Z0B28505?_encoding=UTF8&psc=1

I already had some wire laying around from a stem kit I had.

BUT, if you have some Ethernet cable laying around, that will work better. You would just need some connectors for the other end. This is what I bought and use:

Limited-time deal: Crimping Tool Kit, NAIBAO AWG28-18 Self-adjustable Ratchet SN-DSUB Crimping Terminal Dupont Ratcheting Crimper Plier Set with 1550 Pcs Dupont Connectors and 760 Pcs 2.54mm XH Connectors https://www.amazon.com/dp/B097N8H5Q1/ref=cm_sw_r_cp_api_i_dl_D59CZ2Z2TPSYVM81D598?_encoding=UTF8&psc=1

I used a couple of BigTree BLTouch extension cables I bought on Amazon https://www.amazon.com/gp/product/B08G8B23L7/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1 and ended up cannibalizing both cables to connect my adxl345. I couldn't get it to work after using the adxl345spi tool until I restarted my Pi, then it worked perfectly.

I currently have the stock ender bed with a glass plate.

I plan on getting a pei spring steel sheet with the magnetic sticker. I had hoped to use the existing bed but I checked it with a straightedge and it’s warped enough that I could see light under the straightedge when I put a flashlight behind it. There is a kit on Amazon that includes a milled aluminum bed and silicone bed heater upgrade that I hope will be flat enough.

Here is the 3 point leveling kit I mentioned. Befenybay Modular Y Carriage Plate Upgrade for 2040V Aluminum Profile for Ender3/Ender3 Pro 3D Printer (190mm) https://www.amazon.com/dp/B082ZZ9LSV/ref=cm_sw_r_cp_api_i_5ZY1QHQQB3EA2QEWMPCX?_encoding=UTF8&psc=1

I found some threads about loading meshes and didn’t have time to test anything this morning. My G29 just includes BED_MESH_CALIBRATE (among other general movement commands). So I am generating a mesh before each print. I was reading the documentation and it seemed like unless otherwise specified Klipper was supposed to load the mesh generated during the calibration cycle. I know the BMC command triggers a save config that saves the mesh somewhere but I’ve never specified a profile. I tried including BED_MESH_LOAD on one of my pre-print gcodes but it flagged that as an error.

I use this screen and Klipperscreen, the Pi can mount to the back of the screen and uses the DSI port with a ribbon cable.

https://www.amazon.com/dp/B09J3Y1RRT?ref=ppx\_yo2\_dt\_b\_product\_details&th=1

I'd advise against hooking up a 'raw' relay directly to any GPIO as there is no protection. With other projects, I have used the following with solid success. These work with rPi as trigger voltage is within range. Lastly, do make an enclosure and please take proper safeguards when working with mains.

https://www.amazon.co.jp/-/en/WayinTop-Channel-Trigger-Development-Coupler/dp/B07W5MZ2C7

There are a variety of odroid and orange pi's you can get on amazon cheap that should do quite nicely.

​

This one for example I've used for octoprint before and it works quite nicely.... should do klipper pretty well too.

​

A heatsink is in the extruder part built in and it is quite good. I did find someone who sold his extra V6 heatblocks, heaters and thermistors locally, I doubt they are original, but I didn't want to wait endless shipping times, the results are already better, even though I don't have a silicone sock yet and the thermistor is just lying in the block(it's a non cartridge version), the temps are mostly between 214 and 215.3, but it rarely does dip under 214. Tomorrow, a friend will give me his spare cartridge thermistor, if this won't help, I'll try to flash marlin, do a pid tune there, flashing klipper again, and copying the values, I'm not gonna look foward to that....

I'll just leave this here. ;-)

Very neat project!

My screen should arrive today and I plan to connect it using this interface cable: https://www.amazon.co.uk/BIGTREETECH-Interface-Simple-Suitable-Printer/dp/B08DY43QT7

With this you should be able to connect a screen with 2x EXP ports to a board that has only one EXP port. I'll let you know how it goes..

No, don't use tape . It really needs to be attached physically. I strongly STRONGLY urge you to get a Pinecil soldering iron (best thing I've gotten in ages) and some heatset inserts @ 3mm. No matter what hotend fan shroud I'm using, I insert 2 3mm inserts into the face for the accelerometer mount. I designed a mount for the bed when I measure Y as well so everything is about as plug and play as it can be.

I like the pinecil because within 40 seconds its at 600 degrees. No waiting, no big deal to "fire up" the iron. I just plug it in and by the time I've dug out the inserts or stripped the wires, it's ready. Not to mention how much EASIER it is to wire on connectors, splice fans, etc. I got the pinecil and a shitload of heatshrink tubing assorted sizes and now everything looks professional. :)

But yeah, don't use tape ;)

What you need is to run one wire from your router to a switch, and then from the switch you can run one line to your Pi and a second to your PC. Something like this

https://www.loom.com/share/4a90eacde40446789453bc06a4bc3905

If it gives any issues feel free to let me know and ill just put it on youtube

>per your request i made a video (if it gives u any issues let me know and ill just put in on youtube). https://www.loom.com/share/4a90eacde40446789453bc06a4bc3905 i sort of solutioned it but idk if thats just guessing. Let me know thanks all who are helping.

Quick and easy answer is sftp using Cyberduck. You use the same credentials you use for ssh.

Long-term solution for easy single-file downloads is iTerm2, with the shell integration tools installed. Then you simply type it2dl /path/to/your/file.png in your ssh session and it will download your file.

Out-of-the-box answer is to type mv /path/to/your/file.png ~/gcode_files in your ssh session then go to the G-Code Files tab in Mainsail and right-click on the file and select download.

The screen isn't showing anything when booting.

The screen gets power from the pins and video signal from the HDMI

But I don't have the Manuel anymore

I have this: https://www.amazon.com/gp/product/B0762XXV62

I use it for projects like this and just unzip what I need.

Note that they call it 28 gauge, but it seems this one might be closer to 30.

This is the one I have: Creality Capricorn Bowden Tubing 1.75mm 1M All Metal Ender 3 V2 Extruder Pneumatic Couplers Bed-Level Springs for Ender 3/Ender 3 V2/ Ender 3 Pro/Ender 5 Pro 3D Printer https://www.amazon.com/dp/B081DN6RM2/ref=cm_sw_r_cp_api_glt_i_AGAS9BQB79EWDM6V5NT6?_encoding=UTF8&psc=1

CableCreation Micro USB to Micro USB OTG Cable, Male to Male, Compatible with DJI Spark and Mavic, PS4, Owlet, Android Phone and Tablet, DAC and More,8 inch / 20CM https://www.amazon.com/dp/B01M5GZ3N0/ref=cm_sw_r_apan_glt_fabc_NMGENV80C3RC5JD87D27?_encoding=UTF8&psc=1

It works like a charm! Thanks!

... but unfortunately it can only turn off the USB connection.

It requires a USB connection to the MCU in order for it to attempt to execute the command, so in order to turn on the USB connection I would first need to have a USB connection.

I think I just need to have a hardware solution and install two power buttons: One for the pi and one for the MCU.

I have ordered this 3 times, they are about $3 each and are fully documented and easy to work with.

​

I don't think the built-in display output on the board works at all with Klipper.

You can get a cheap display and hook it up to your Pi, that's what I did.

https://smile.amazon.com/dp/B0872S57HG/ref=cm_sw_em_r_mt_dp_9EP04DRQ4AKHCFKVWFMD

I added an external wifi module to my 3B+ to solve this same issue, plug and play (literally didn't do any config work at all), blocked the onboard wifi in my network so I can reconnect if there's any issues later on.

By the dongle, I mean you could buy one of these little guys:

https://smile.amazon.com/TP-Link-wireless-network-Adapter-SoftAP/dp/B008IFXQFU/

Then, assuming you're using windows, you can create a network with the adapter, connect your pi to the network you just created and then you'd be able to access it via that.

Additionally, if your pc is connected via ethernet, and you already have a wifi card in your computer, you can just use that wifi adapter you already have to create a wireless network.

This link explains how to do it:

On my machines, I run a Meanwell RS-15-5 as my "standby" power supply. On the Ender-3 based machine I've got it wired to inject power via the 5-pin BLtouch port, as it has a +5v lead that wires to the back (output) side of the step-down regulator in the board itself. I don't actually run that machine over the USB port for power, but it SHOULD work fine.

Through a common Pi 4, you can get around 1A@5v from the USB ports, which has been plenty to run my FLSun Q5 in standby across the bus, though it is based on an MKS Robin Nano board, and not the exact same creality v4 board.

The Pi Zero likely will push via USB whatever current it's power supply will produce, so you may not want to run a 4 amp PSU with it, as I don't believe there are any safety controls and the traces are probably well undersized for that power level. Alternatively, you could just wire yours to inject power via the bltouch plug as well. My first power injector design was just a 2" long 5-pin JST-XH to JST-XH with a pair of extra wires tapped onto the power and ground lines, and I had the BLTouch still wired normally through it. I've since modded a bit more to get access to all the available CPU pins, and my Bltouch is now wired onto the bltouch IN sense pin (as my OUT control) and the Z endstop, and I use the old BLTouch IN as my relay control. The OUT shouldn't be used due to the STM32 boot loader cycling it on and off at power up, and Z-stop can only be used as a sense pin due to hardware design.

Nice. I have a one plus nord n10 5g that I'd like to run klipper from. I just got a Pi zero 2 and it worked for about 3 out of 5 short prints and last print it was completely dead after an overnight print failed. I kept having trouble with it losing connection so I think it was on the brink of failure the entire time. Now the LED doesn't even light up.

I'm considering something like this: https://www.amazon.com/dp/B08RRY61YS

Just not sure if this phone will allow charging or if I can root this phone(pretty sure it's updated pretty well). If I can't charge through usb I'm guessing the battery could be removed and just solder a 5v USB charger directly to the PCB?

> (actually tried at some point to build on amd64 but crossbuilding seems to be very raw yet in docker world).

Have a look at https://www.docker.com/blog/multi-arch-images/ - it describes the process. I've used it before to build for my raspi on my desktop pc.

I'm currently experimenting with setting up a moonraker clean image at https://hub.docker.com/r/terrasque/moonraker - the basics seems to work, but it's probably a lot missing still.

Currently can be run like this: docker run -it -p 7125:7125 -v /tmp/klippy_uds:/tmp/klippy_uds terrasque/moonraker and the api answers at least. Going to connect a frontend to it later today and see just how much is not working

https://codeshare.io/ay67Kb this is my printer.cfg i simply took the example one for the ender 3 and made some changes to suit my specific setup as well as the bltouch

I honestly think the stock hotend is perfectly fine but upgrading to an all metal heatbreak becomes essential IMO. Many people don't use them right. You should polish up the inner bore by hand, especially on cheaper ones, and install it into the heatsink with thermal paste. I print everything from wood PLA at 190C to harder materials up to 300C with no issues at all. I do use a 40x25 noctua heatsink fan to give it some extra help though.

I did it! It's not perfect at the hot end, but I wanted to make everything modular so it was easy to replace bad parts without having to chop the harness apart.

Here's the link to the wrap: 25ft - 3/8 inch PET Expandable Braided Sleeving – Blackblue – Alex Tech braided cable sleeve https://www.amazon.com/dp/B074LVPH3J/ref=cm_sw_r_apan_glt_fabc_KBBWVN587BVB72AZYAAB?psc=1

That could be; i'll have to do some digging.

The one I had purchased was the ADAFRUIT one and the reviews on Amazon looked promising for doing the input shaper tasks in Klipper. https://www.amazon.ca/gp/product/B01BT4N9BC/ref=ppx\_yo\_dt\_b\_asin\_title\_o04\_s00?ie=UTF8&psc=1

Personally I used AITRIP 5pcs GY-291 ADXL345 3-Axis Digital Acceleration of Gravity Tilt Module for Arduino IIC/SPI Transmission https://www.amazon.com/dp/B08VD7325C/ref=cm_sw_r_cp_api_glt_fabc_WVDPEFTGEY3243Q39JDQ?_encoding=UTF8&psc=1

One thing to save a ton of time troubleshooting, use a network cable or something shielded or with twisted pairs. I spent hours thinking it was the sensor or I did something wrong. Nope just don’t use 22 gauge ribbon cable, tho it looked really nice and flexible.

I'm using this one, works fine.

HiLetgo GY-291 ADXL345 3-Axis Digital Acceleration of Gravity Tilt Module for Arduino IIC/SPI Transmission https://www.amazon.com/dp/B01DLG4OU6/ref=cm_sw_r_apan_glt_fabc_DC2W15P78K2941ZD56C4?_encoding=UTF8&psc=1

I just recently finished my build with 2208's and after doing the buzz test at stock current I had on Marlin I noticed intense vibrations and slight missed steps, but most concerning was the heat generated by the 2208's. I reluctantly installed a few stepper smoother boards. Also installed a stepper driver cooler mod to my main board. Now she works like a charm.

Finally, what stack are you using? I noticed that octoprint on a pi 3B was stupidly buggy/slow when I had large/lots of plug-ins enabled.

I'm using this at 12v, it's much cheaper than a noctua and pushes enough air to not give me any problems printing at up to 260C with a copperhead heatbreak in an otherwise stock ender3 hotend, but I've got a printed shroud. Actually a hydra which has really poor airflow around the hotend heatink.

I had issues with a 12v 30mm fan on an e3d v6 in a prusa mk2 extruder, i've got the same 12v quiet fan and a 40->30mm reducer duct which seems to work ok, but I've just had the heatset inserts arrive so it's getting a bear/afterburner X/E setup with said 40mm fan.

I'm using the spare heater output on a gt2560a board to run my hotend fan on the prusa becasue it doesn't have a power relay sorted out yet but it's in the pipeline, but control box cooling, hotend cooling and enclosure fume extraction will all eventually be done with mosfets either from pins on the mainboard or the PI.

I have a handmade transitor fan controller running a fan to cool my control box enclosure from the RPI from when it was on marlin, and some python code but that's going with a mosfet soon and it's going to stay outside of klipper as it needs to work all the time not just when klipper is running.

![Adafruit ADXL345 - Triple-Axis Accelerometer (+-2g/4g/8g/16g) w/ I2C/SPI [ADA1231]](https://m.media-amazon.com/images/I/71996YzXQvL._SL500_.jpg)